Dropwatching instruments

For those who need to evaluate and optimize the jetting on a regular basis.

Optimization services

For those who need optimal printing parameters for a specific application.

How we help

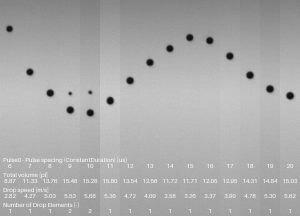

Droptimize helps you to find the best printing parameters for your inkjet application. We use our software, which combines dropwatching with big-data, to evaluate large numbers of waveforms and identify optimums.

Everything that can possibly influence the jettability in your system is taken into account: printhead, driving electronics, ink system, and ambient conditions. All parameters, sensor data and results are stored in a database, allowing us to easily compare printheads and inks even at a later stage.

We use our proprietary software and instruments to provide optimization services with a standardized workflow that guarantees the reproducibility of our path to the best solution. These services allow anybody in inkjet to achieve the full potential of their applications without investing in the R&D equipment and developing in-house expertise, and are expecially well suited for one-time optimizations.

For those who need optimizations on a regular basis, we recommend to bring the power of our big-data solution in-house by purchasing one our instruments.

How are we different?

Adapted

We take your whole inkjet printer setup into account: ink system, print system and ambient conditions.

Standardized

We propose standardized, reproducible evaluation and optimization solutions. All tests and results are stored in a database, allowing us to compare printheads and inks even at a later stage.

Experienced

We have over 12 years of cumulated experience in the development of novel inkjet solutions.