Products

DOT-S

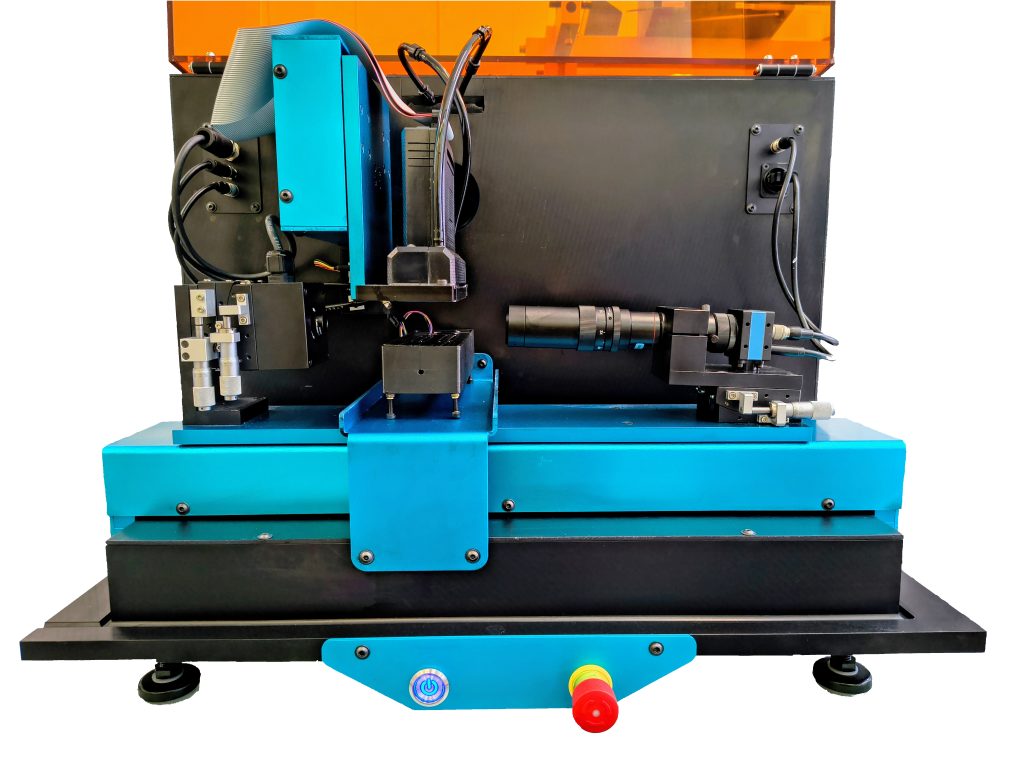

The DOT-S is an advanced dropwatching instrument fully integrating our big-data software. It already supports the most common printheads and driving electronics, and can be customized for special applications.

DOT-S Key features

Click on the features to display additional information.

Enclosure

Several enclosure options are available to ensure the operator's safety:

- No hood for installation in an existing fumes hood.

- Transparent or UV-proof hood for standalone use. In this configuration, the fumes outlet must be connected to a centralized ventilation or a separate extractor.

Printhead Holder

The printhead holder is fitted to support the selected printhead. This part is precisely machined to ensure a reproducible positioning without any alignment procedure. All the most common printhead models are already supported, and customizations are available for special cases.

Mist Sensor

A laser-scattering sensor is mounted within the enclosure to monitor sub-micrometer aerosols. It is used to monitor the misting for optimizations as well as to ensure the operator's safety.

Active Dropcatcher

An active dropwatcher is mounted below the printhead. It generates an airflow ensuring that the ejected drops are properly collected and discarded.

Motorized 3-Axis System

All axes are motorized to ensure a fully repoducible positioning on the nozzles. It is fully integrated, which allows to automatically scan all nozzles for stability measurements.

On-Board Computer

A powerful computer as well as all the necessary electronics are integrated into the back of the instrument. The dedicated computer manages all the controls and databases directly. No installation or software is required to access it since it generates a web interface accessible from any device within the network.

Optical Module

The optical module consists of a camera with a zoom combined with a strobe and triggering system.

The optics typically allow to reach spacial resolution below 0.5µm with with single-flashes below 100ns. In addition, the angle of the camera and strobe can be adjusted in the 0-6° range to fit the different nozzleplate shapes.

An automatic position and spatial resolution calibration is implemented to automatically map the FOV to the nozzles after changing the zooming factor or angle.

Specifications

| General information | |

|---|---|

| Dimensions (L x W x H) | 60 x 40 x 40cm |

| Weight | 35 kg |

| Power supply | 24VDC 10A (power supply provided) |

| Motion | Motorized XYZ axis with axial play <5µm |

| Hood | Protective hood with extraction and filtration (optional) |

| Compatible OS | Any with a web browser since the app runs in a web page hosted by the instrument |

| Image acquisition | |

|---|---|

| Spatial resolution | 0.4 – 2.5µm per pixel, with adjustable zoom |

| Flash duration | 20 – 10000ns |

| Camera framerate | Max 50 FPS in full resolution |

| Sensors | |

|---|---|

| Temperature | |

| Humidity | |

| Misting |

| Dropcatcher | |

|---|---|

| With air aspiration and waste collection |

| GUI | |

|---|---|

| Live preview with manual controls | |

| Waveform editor | |

| Inksystem editor | |

| Test session editor | |

| Results visualization with dedicated algorithms |

| Test parameters | |

|---|---|

| Flash delay, flash duration, frequency, grey level, idle time, nozzle IDs, Z-offset, drops per image, jetting load, waveform IDs, inksystem config IDs, number of repetitions |

| Extractable values | |

|---|---|

| Drop speed, drop volume, jetting angle, jetting status, drop classification, number of drop elements, drop XY position, number of mist per frame, stability of any of the previous | |

| 2D or 3D contour interactive plots with preview of the dropwatching image at any point | |

| Stitching images over any of the test parameters with any values as label | |

| All raw values in Excel / CSV and all raw images |

| Applications | |

|---|---|

| Waveform optimizations over any parameter | |

| Performances comparison with previous tests in the database | |

| High-Frequency optimizations up to 200kHz | |

| Long-distance jetting optimizations up to 35mm | |

| Open nozzle time optimizations such as tickling | |

| Misting optimizations for reduced maintenance | |

| Automated nozzle check across the whole printhead | |

| Inksystem parameter and temperatures optimizations |

| Database | |

|---|---|

| All waveforms, inksystems and test session parameters | |

| All raw dropwatching images | |

| All drop features | |

| All sensor values (incl. printhead and inksystem) |

| Supported hardware | |

|---|---|

| Printhead brands | Ricoh, Fujifilm Dimatix, Konica Minolta, Seiko, Epson, others upon request. |

| Driving electronics brands | Meteor, GIS, Aewa, Polytype, others upon request |

| Ink Delivery Systems | Droptimize Dropressure for endshooter printheads, any other can be used, and integrated in the software upon request |